CRESCO, PA — Weiler Abrasives, a provider of abrasives, power brushes and maintenance products for surface conditioning, is offering its Weiler Consumable Productivity (WCP) program to help end users better manage their abrasives costs and increase productivity. The WCP program tests and evaluates abrasives to compare product life, reduce cycle times and increase efficiencies.

“The WCP program can bring real value to end users, especially if they are experiencing bottlenecks in their operations, have short abrasive life and want to improve

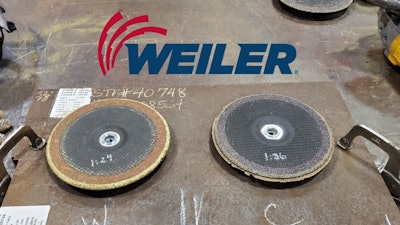

The program involves time studies and observation of abrasive usage to gather quantitative data that can be measured and verified, leading to a repeatable solution. Weiler Abrasives representatives look at how abrasives are used, how long they last and how productive they are. It involves five steps:

Evaluating the value related to purchasing the abrasives

Real-life testing at the company’s facility

Establishing a baseline through testing

Collecting data and establishing averages through product evaluation

Reviewing findings and creating an actionable plan

By comparing several products throughout the process, Weiler Abrasives provides a recommendation for the best, most productive abrasive for the application.

For more information, visit Weilerabrasives.com/Multipass-Consumable-Productivity.

Weiler Abrasives Group is dedicated to forging collaborative relationships with our customers in diverse markets — Metal Fabrication; Industrial Production; and Maintenance, Repair & Operations — to tackle their toughest cleaning, grinding, cutting, deburring and finishing challenges.