Industrial distributors come in all shapes and sizes. From mom and pop operations to global enterprises, these businesses sell products from multiple manufacturers to a wide range of customers in numerous industries. For many of these companies that’s the bulk of what they offer; a lot of products at competitive prices and then they move on to the next customer.

Today’s manufacturers need more than an order taker or a supply line of manufactured goods. In order to succeed they need a partner they can count on to not only provide good products at fair prices, but a distributor that brings more value and solutions to issues. What companies are looking for is a specialty industrial distributor (SID). The trick is finding the right SID. Below are tips to help narrow down your search for the right partner for your needs.

The right parts at the right time

Manufacturers should look for an SID that can provide not only good products at a just price, but also the right OEMs and easy to secure local inventory. Using OEM parts comes with a warranty and in many instances, matches up best with existing installed infrastructure. An aftermarket part might be cheaper, but in many cases does not have a warranty and might be inferior because of the use of lower-quality materials.

Having the right part available locally is nearly a necessity in today’s economy. When a part breaks, repairs need to be done quickly and correctly. When paring down a list of distribution partners, check to see if they inventory a large amount of equipment and parts. Stopping a manufacturing line for any length of time is expensive and unless it’s a scheduled stoppage, most manufacturers don’t want to disrupt the supply chain of their products to customers. Making sure the right parts are within hours of the operation and not days, is critical.

Service beyond the sale

Providing the right part in a timely manner is not a stretch for many companies, but having a broader vision of plant processes is. It’s an easy thing to state in a brochure or website, but service after the sale is truly what separates vendors from partners. Plant management should look for those SIDs that have the technical skill, expert service and repair capabilities as well the foresight of seeing the plant as a whole entity in order to support the entire enterprise.

A stand-alone pump vendor or valve house goes into an application focusing on a single product. A strong SID — in addition to being able to quickly source a variety of technical, engineered products — will review the whole plant process in order to apply the right solution. Regardless of the equipment involved, they will understand the relationships between a valve, pump and instrumentation and can apply solutions that benefit the customer as opposed to just looking at it as a product sale.

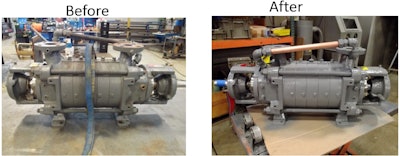

A case in point was a chemical plant in the Midwest that was having repetitive failures on a boiler pump. A local repair shop assumed it was an issue with the pump, but after replacing it a few times the issue persisted. The customers came to us and our pump application engineers examined the pump and saw no issues. They then looked at the entire system where they found the problem; a valve was the true issue causing the pump to malfunction. The engineers redirected, rearranged and redesigned the pipe layout and specified a valve that was more conducive to the application. Once the pump was repaired and in place with the new valve, the chemical plant’s line was running smoothly again.

In this instance, being able to view the situation holistically and not as individual parts, allowed the application engineers to see the issue clearly and implement the right solution.

Get off to a good start

After investing in equipment that your plant is depending on, it only makes sense to lean on a distributor to help start and maintain that equipment to the best of its ability. Adapting parts or a series of parts to a plant environment and installing with new or repaired parts within existing equipment can at times be tricky. Choose an SID that offers experienced start up assistance for new and refurbished equipment. New equipment might arrive in perfect condition fresh from the factory, but plant conditions might not be the same. Having an experienced team commissioning your new or overhauled technology can save time, money and aggravation.

To pick up on the earlier case history, when installing a new piece of equipment such as a valve, a full-service SID can also make sure the gear is calibrated correctly, ensure that the instrumentation is regulated appropriately whether it’s pressure temperature level or flow. Startup commissioning can also include looking at the pump equipment to be sure the foundation is level and confirm perfect position with a laser alignment on it. Finally, making sure that the equipment is plum in all aspects from the motor to the wet end of the pump.

Removing a piece of apparatus for repair and bringing it back online also needs an experienced hand. Performing startup assistance on repaired work or on existing equipment should start with a survey and through the analysis of the products; work with the customer to plan the change out or service to avoid any downtime.

Avoid downtime by being proactive with monitoring and repairs

Regular predictive and preventive maintenance protects your investment in critical assets and helps safeguard business-critical infrastructure to operate efficiently, safely and reliably. In order to be more proactive rather than reactive to maintenance needs, monitoring can be an affordable and judicious service to seek from your SID.

For some of customers’ pump equipment, monitoring and performing vibration analysis when necessary as well as working with the plant on a predictive maintenance schedule can pay dividends. Monitoring allows the SID and plant management to know if a few of the pumps are moving towards failure mode in the next six-to-eight weeks. Another set may be running in a cautionary state meaning that they are operating, but might need to be replaced during the next plant shutdown. And still others show no signs of failure. The benefit of monitoring is the ability to schedule downtime rather than having to react to it. Monitoring also allows plant management to see trends and make changes to processes to avoid issues in the future.

Jody Linnig, Senior Vice President of Sales at FCX Performance

Jody Linnig, Senior Vice President of Sales at FCX PerformanceEvery product is designed with components that have a limited life, which can bring anxiety to a plant manager. Some of these components have longer lives than others and this depends on the design of the component itself, its function and the operating conditions to which the product is subjected. Having the right specialty industrial distributor on board as a partner to procure the right parts quickly, monitor and maintain plant systems can help alleviate that stress and be a valuable asset.

Jody Linnig is Senior Vice President of Sales at FCX Performance — No. 30 on Industrial Distribution's 2017 Big 50 List.