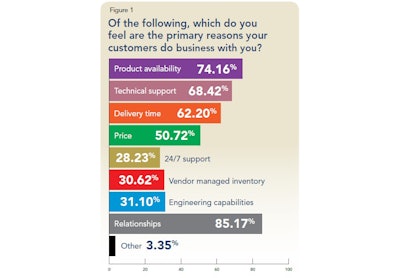

Because I work closely with wholesale distributors regarding inventory optimization and inventory right-sizing through the use of excellent inventory reporting software, I was fascinated to see a recent article and survey in Industrial Distribution. Their “Survey of Distributor Operations: Value of the Distributor” revealed that when distributors were asked for the primary reasons why their customers do business with them, relationships and product availability ranked at the top and were considered equally important at 80.6 percent. Does that strike you as interesting?

Much of the focus on building a successful business is correctly focused on the importance of building and flourishing relationships. Many books have been written on the subject and businesses invest in all sorts of seminars, webinars and training about how to value the customer and how to build those relationships. In fact, it is a given to say that “Relationships are everything to the success of a business.” While this is true, what surprised me was that distributors were able to recognize the value of right-sized inventory. What good is a great relationship with a client, if every time they want to buy from you, that item is back-ordered?

To be sure, the value of a distributor is interwoven with inventory. So why are so few distributors as committed to investing in inventory reporting tools and inventory optimization solutions that could really help their company ensure that they have enough of the proper inventory items in stock at the right time? (I’m also well aware of another serious problem of having too much inventory or dead inventory as shown here)

Employing The Right Inventory Optimization Techniques

Here are four tips to stocking enough inventory to keep your important customers happy:

1. Right Facts and Right Forecast. To keep up with demand you will need enough inventory to meet whatever your forecasted sales will be by analyzing your historical sales data. A good forecasting tool can really help you use the right facts and provide the right forecast. Although no forecast is completely accurate, the better you do at forecasting, the closer to your true inventory needs you can get. Consider the items that are most difficult to forecast but are sure to sell. You can afford to stock a little more of those items without the risk of them becoming obsolete.

2. Decide the right level of stock. Determining the ideal amount of stock to order and keep on hand really depends on your size, your cash, and your type of business as well as the type of stock you handle. If you lack warehouse space, you may be able to keep little or no stock and negotiate with suppliers to deliver stock as you need it. You should constantly monitor your inventory levels to be sure that you do not run out, or better yet, rely on inventory optimization solutions to help you. And always choose reliable suppliers who can get you your inventory quickly and on-time.

3. Choose the right time to re-order. Setting the right re-order point is important because while your goal is to always have enough inventory to meet customer demand, you don’t want too much inventory since that ties up your capital unnecessarily. The re-order point (ROP) is the minimum amount of an item to be held in stock, such that, when stock falls to this amount, action must be taken to replenish that particular inventory stock. To identify this point, you need to know the lead time it takes to acquire that item from the supplier. This is critical because that’s how long you’ll have to wait before new stock arrives, so you need at least that many days’ worth of supply to satisfy your customers while you wait! You can determine your “re-order point” by using the simple formula:

Reorder level = Average Daily Usage rate x Lead Time in days.

If you sell an average of 100 Hershey’s Milk Chocolate Bars a day (my personal favorite) and it takes you 5 days lead-time to replenish your supply, your reorder point is when your stock drops to only 500 candy bars! (And to keep a great customer like me from not being able to support my chocolate habit, you definitely need to add some safety stock!)

4. Have some “safety stock” to protect against shortages and unexpected events. It is a good idea to prepare for the unexpected! Having some safety or buffer stock protects you against unexpected occurrences like rapid changes in demand, seasonal business considerations, and unexpected shortages. There are several more complex formulas you can use to calculate this which include finding the standard deviation from the average of both the daily usage and the lead time, but a more simple formula is:

Safety Stock = (Maximum Daily Usage − Average Daily Usage rate) × Lead Time in days.

So back to our candy bar example; If your maximum daily usage was 150 (No, I did NOT buy the extra 50) your safety stock would be calculated as (Max daily usage of 150 minus the Average Daily usage of 100) x 5 days lead time. Therefore, your safety stock is (150-100) x 5 =250. The amount of safety stock that you actually need really depends on how prone your business is to rapid changes in demand, and the time of year if you are a seasonal business.

Eric Jensen, Account Executive at Cutwater Solutions

Eric Jensen, Account Executive at Cutwater SolutionsI’d like to hear how you calculate re-order points and safety stock. And remember, if you are a distributor, while your value may be based on your relationships with your customers, flourishing those relationships could be dependent on having optimal levels of inventory to satisfy customer demand. Finding the right inventory optimization solution that assists with more accurate forecasting and just-in-time inventory management, could be the first step to ensuring that you improve your customer retention levels and cut costs.

Eric Jensen serves wholesale distributors through cutting edge inventory software for Cutwater Solutions.