A lot of focus is put on ways to increase revenue in a business. Often it involves finding new sources of income or raising prices on products. Lately, more effort has finally started going toward things like warehouse worker productivity and ways to save money.

This is definitely a step in the right direction as saving money is a great way to increase profit margins. What also should be added to the list, however is warehouse maintenance. Keeping the warehouse functioning efficiently goes a long way toward a safe and productive workplace that helps to save money.

In this article, I will go over several steps you need to take to keep your warehouse maintenance on point.

1. Start with urgent repairs

To maintain your warehouse there has to be something to maintain. This means that you have ot make right any of the areas of the warehouse that are not working or are broken. Even outdated equipment and structures need to be repaired or replaced to start out on the right foot.

For instance, loading dock repair needs to be a priority so hiring a company like Miner Corp is essential to make sure that it is a safe and effective part of the warehouse.

Once everything is working as it should then you need to start your maintenance routine on a regular basis to make sure it is running like a top.

2. Use technology

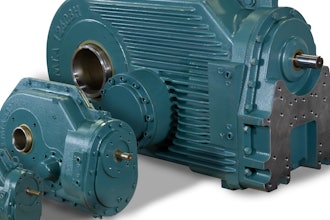

One of the biggest benefits of updating equipment is that you can use the latest technology to keep it running at its peak. There is software that you can use that gives you a detailed monitoring of machinery so you don’t have to wait until it breaks down or even scheduled for routine maintenance.

All too often, managers wait until there is a problem to then fix it. This costs money to fix as fixing is more expensive than maintaining. And, downtime costs a company quite a bit as well.

Even waiting for the scheduled maintenance to occur is a mistake. Having software analyse the systems can let you know when maintenance needs to be done. If there is a leak you will know right away. If something needs lubrification even before it is scheduled then you take care of it before it causes a breakdown.

3. Do routine checks of the structure

A lot of attention is placed on the machinery and equipment as it is the most expensive to repair or replace. What gets little attention are things like the shelves and other structural elements.

Do a routine check to make sure that your shelves are not rotting or straining under the weight of the contents on them. You should also monitor things like pallet racks and other storage equipment.

4. Weatherize

A leaky roof can cause immeasurable damage to your property and the goods in your warehouse. Make sure to monitor if your roof is leaky or other parts of the structure are equipped to handle the weather.