The supply chain sector is a fast-paced environment, and technology has become an essential ally. Its role is more than a support mechanism; it's a strategic tool redefining the rules of engagement. So, let's jump in and discover how technology can be your side-kick in supply chain management.

The digital era has ushered in transformative technology to streamline supply chain management. Among these, the P-F interval and predictive maintenance stand out. The P-F interval, indicating the time from a potential failure's first detection to its actual occurrence, is a cornerstone of predictive maintenance. By identifying these failures early, corrective action can be planned before the equipment fails.

Sensors embedded in supply chain equipment play a vital role here. They monitor parameters like vibration and temperature in real time. This data is analyzed by predictive algorithms, enabling early anomaly detection. Such tech applications, particularly predictive maintenance, are increasingly indispensable for modern supply chain management. They not only cut maintenance costs but also prevent operational disruptions, demonstrating their key role in achieving supply chain goals.

The Game-Changer

Digital commerce payments have become increasingly important in supply chain management, offering various benefits to manufacturers, such as:

- Expanding buyer networks. Digital commerce payments can help manufacturers smooth out their transaction processes. This not only enables them to manage larger buyer networks, but also helps them tap into a broader customer base. The resulting expanded network can lead to increased sales opportunities and higher revenues.

- Informing decisions. Digital commerce payment solutions generate a wealth of transactional data. This data can be utilized to make informed decisions, helping manufacturers stay competitive. By leveraging a data-driven approach, manufacturers can stay agile, resilient, and can offer optimized payment solutions tailored to their buyer profiles.

- Reducing costs. Digital payments allow manufacturers to cut costs effectively. They streamline various financial tasks like invoicing and cash flow management. This automation not only reduces the risk of errors, but also saves time, allowing manufacturers to focus more on their core competencies.

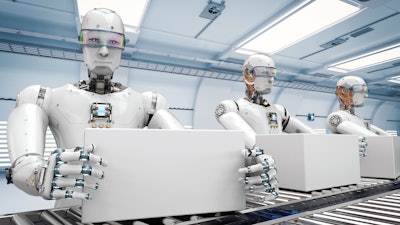

While digital commerce payments offer a promising way forward for manufacturers, the implications of technology on supply chain management go beyond the realm of transactions. An increasingly important innovation is set to reshape warehouse operations — the advent of intra-logistics smart robots.

The Power of Intra-Logistics Smart Robots

The use of intra-logistics smart robots for warehouse operations is expected to rise significantly, with predictions that 75 percent of large enterprises will have adopted this technology by 2026. This shift is driven by the numerous benefits these robots offer, including increased efficiency, productivity and accuracy in warehouse operations.

They also reduce the reliance on manual labor, which can lead to cost savings and improved safety. However, the transition to using smart robots also requires substantial investment and may necessitate changes to existing warehouse layouts and processes. Notably, the COVID-19 pandemic has accelerated the adoption of such technologies, as businesses strive to maintain operations amidst social distancing regulations and labor shortages.

Advanced Analytics, AI and Data Science

We're witnessing a sea-change in supply chain management, fueled by advanced analytics (AA), artificial intelligence (AI), and data science. By 2026, over 75 percent of supply chain management application vendors are expected to incorporate AA, AI, and data science in their applications.

Supply chain organizations are also embracing these technologies. By 2024, it's projected that half of these organizations will invest in applications supporting AI and advanced analytics capabilities. These tools enable better-informed decision-making and facilitate predictions for future outcomes.

Furthermore, approximately 38 percent of supply chain organizations are currently upgrading their technologies to enhance end-to-end processes. The fusion of AA, AI, and data science is revolutionizing supply chain operations — through predictive analytics for forecasting demand, advanced risk management, route optimization for efficient logistics, and insights into customer behavior for better service.

Additionally, it promotes sustainability by identifying inefficiencies for waste reduction and smarter resource allocation. For industry leaders, adopting these technologies is not an option — it's a necessity.

Choosing the Right Tech

Selecting the optimal technology for your supply chain is a pivotal decision, one that can significantly influence your business's operational efficiency, adaptability, and overall performance.

To ensure the chosen solution aligns with your specific needs and supports your growth trajectory, there are certain critical factors to consider. These include:

- Configurability. Look for software that can be configured to fit your specific requirements. This might involve the ability to configure views, turn features on or off, and make additions or adjustments without the need for custom code.

- Vendor expertise. Seek a vendor that has a strong presence in the sector and can offer guidance based on their experience supporting other companies of similar size and maturity to yours.

- Ongoing support. It's important that the vendor can provide strong support during and after the initial implementation stage. As your business needs change, your technology partner should be able to scale and support your company's growth.

- Advanced capabilities. Consider the advanced capabilities you need to support your strategy. This might involve the ability to connect data, decisions, and operations across the supply chain, and the ability to view and connect your entire supply chain.

- Reviews. Look at reviews from actual customers to get an idea of what it's like to partner with a specific software vendor. These can provide insights into levels of support, features and capabilities, and how the technology implementation has helped with supply chain optimization.

- Cloud-based or on-premise. Determine whether a cloud-based or on-premise solution will be better for your business. This will depend on your existing tools and business needs. Cloud-based solutions often offer advantages in data speed, integration, and security, as well as higher flexibility and scalability.

- Cultural fit. A good cultural fit between your company and the software vendor can increase the probability of a successful partnership. The vendor should be able to provide tools to enable your supply chain planning maturity progression and draft a practical business case based on your specific needs.

The Takeaway

Thriving in the fast-paced supply chain sector requires technology as a strategic ally. In a nutshell, the future of supply chain management hinges on the strategic integration of cutting-edge technologies.

Decisions about implementing these technologies should be well-calculated, factoring in the unique needs and growth trajectory of each business. Embracing this digital evolution isn't optional but a necessity to achieve operational efficiency, financial effectiveness, and a competitive edge in today's fast-paced, data-driven business landscape.

Bryan Christiansen is the founder and CEO of Limble CMMS.