This article originally appeared on the ADS Solutions Wholesale Distribution Blog. You can view it here.

The need for distribution software tools to help with inventory optimization has grown in recent years as distributors have struggled with an uncertain economy, rapid changes in the global marketplace, and pressures from new market entrants like Amazon Supply that threaten their already tight margins. Inventory optimization has evolved as a real science that is being embraced by distributors of all sizes. While it might have been only Fortune 500 companies that were early adopters of inventory optimization practices, more and more, we now see small and mid-sized distributors understanding the benefits of inventory optimization and using powerful software and technology to guide their inventory decisions.

Reducing inventory within certain categories or improving inventory turns are two excellent ways to please your shareholders or your boss. But true inventory optimization requires a complex, multi-faceted approach that factors in the many variables that drive your distribution business’ profitability. Given the complexity, there are clearly right ways and wrong ways to go about it. Here are some mistakes to avoid – three scenarios that could lead to inventory being optimized in a way that could actually hurt your business:

Scenario 1: Your accountant advises you to reduce your inventory by more than ten percent, so you cut safety stock.

It’s easy for outside advisors or management to glance at a balance sheet and say “cut.” Inexperienced managers can do more harm than good by doing what is easiest: cutting safety stock. Problem: In order to meet a ten percent overall inventory reduction goal, safety stock might have to be cut by 25 or 30 percent. Reducing safety stock this dramatically can have serious implications for customer service levels and is not a good inventory optimization strategy when used in isolation. Proper inventory optimization requires a much more thorough analysis and thoughtful planning than cutting in this one finite and very important category.

Scenario 2: Your boss wants you to improve your service levels without an increase in inventory, so you encourage sales staff to spend more time with each customer.

Problem: The added time your staff spends taking and processing orders costs your company money, and labor is not cheap. Although with your new competitive pressures from price-driven mega-distributors like Amazon Supply, it is clear that you want to nurture customer relationships and leverage your staff to build value-added services, but doing this by merely spending more time with each customer is not the most economical solution to the problem. Instead, try optimizing your existing inventory, and watch service levels automatically fall in line, without added labor expense. Then, create campaigns to build your value-added services that have the best bang for their buck.

Scenario 3: You need to improve your cash-flow or pull cash out of your business to invest elsewhere, so you cut expenses by reducing head-count.

Problem: This may give you short-term cash-flow relief, but in a small business environment, it can overburden remaining employees, and you might see a decrease in morale and overall productivity because your staff simply has too much to do in too little time. Over-burdened employees are known to cut corners and make mistakes. And if it’s your sales staff you’re cutting, you may be shooting yourself in the foot. Solution: Optimizing your inventory gives you the ability to free-up cash for other uses in your business, but, if done correctly, has no negative implications for sales, service, employee productivity, or order fulfillment.

What Is Inventory Optimization?

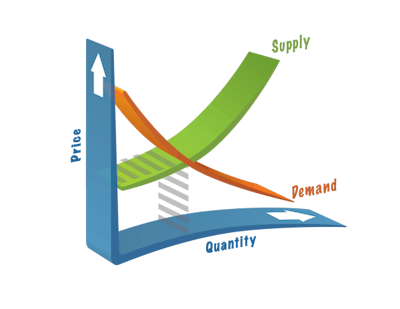

Inventory optimization is the process of using mathematical algorithms to strike the perfect balance between supply and demand. It determines your most profitable inventory mix and specifies the level of inventory you must keep of each item that will allow you to fulfill the maximum number of orders with the least amount of stock on hand. In short, when you optimize your inventory, your distribution software helps you figure out how to do the most, with the least.

Start with Inventory Stratification!

Start by appreciating the complexity of what inventory control software can do for you. In order for mathematical algorithms for inventory optimization to work, inventory cannot all be grouped into the same bucket. Because the business drivers of each inventory category cannot be optimized in the same way or at the same pace, you need a systematic way of defining your inventory categories based on your historical sales and your business goals. You need a categorical identification method to weed out your inventory’s strong areas from its weaker performers. Identifying these discrete categories is a different process for each business.

As time goes on, more and more businesses are relying on distribution software to drive their business success. The amount of information we have available to us today is overwhelming, and managers could spend thirty percent of their time just trying to analyze it. Instead, let your distribution software help inform your inventory optimization decisions, so you have more time to do what it takes to keep your business growing and profitable.