For Atlanta-based Verusen, the goal is to lead a new era of supply chain by “shifting the landscape” of how global organizations approach their materials management strategies.

At the recent ISA23 conference in Phoenix, Verusen unveiled a new supplier app that leverages artificial intelligence to help industrial distributors, integrators and suppliers improve demand visibility.

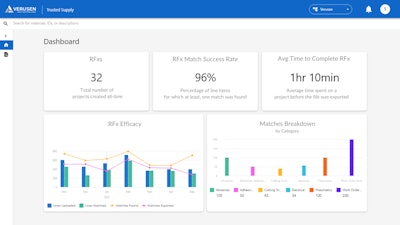

Dubbed “Trusted Supply,” the application has been purpose-built for suppliers, featuring natural language AI models to enable them to respond more effectively to customer needs, regardless of system or data quality. Today, the offering is designed to streamline the RFx process, exponentially improving the match rate for materials requested by customers and prospects — and enabling suppliers to respond in hours instead of weeks.

We recently chatted with Verusen Founder and Chief Strategist Paul Noble on the new launch and what it means for industrial distributors. Responses have been edited for length and clarity.

ID: Paul, do you mind starting by giving us the high points on Trusted Supply?

Paul Noble: It's kind of a natural evolution and extension of our platform to support industrial distribution integrators — suppliers of manufacturing end users. We're a supply optimization company and we help large manufacturers optimize their inventory, their spend, and their risk across their supply chains. We do that in a different way than a lot of traditional solutions because we've developed technology that can help eliminate the need for data cleansing to populate inventory or spend algorithms or whatever it may be.

It could be the same bearing, but it could have a thousand different names. Everyone names these physical goods, which changes their digital profile, and then it makes it very difficult for users and suppliers of industrial distributors to work together. I saw that as the biggest need. So we developed technology that could essentially overcome that challenge and eliminate that problem by being able to read this data in systems like SAP or Ariba or whatever ERP or “Frankenstein” of systems you use — just be able to say, “I call it this, you call it that, but it's really the same thing” or “these are duplicates of each other.”

Paul Noble, founder and chief strategist, VerusenVerusen

Paul Noble, founder and chief strategist, VerusenVerusen

And so we've had great success driving cost savings and working capital, eliminating tail spend, augmenting people because we do this by using AI and deep learning and trained models specifically on MRO and those types of materials. Trusted Supply [is] based on a strong need. Over the last couple of years, the natural evolution was, “We want our suppliers to be more connected to our needs” … and, “I still call it that, but we know it's the same thing and [now] I can tell you what I need so you can service me.”

That's what Trusted Supply is at the core, because industrial distributors and suppliers have a problem with their customers’ data being bad. And so Trusted Supply is solving the quote or the bid process where if I receive an RFQ from a potential customer or current customer, it's very manual; it's a very siloed activity, and it takes a lot of time for an industrial distributor to respond to that. It could be weeks before they could get through that and return back something. And that's just really inefficient. So, we talked to a lot of large and small independents, large national distributors, large integrators, and that was the biggest pain that we could solve for them is being able to accept this dirty data set and run it against their catalog and be able to quote faster. So, take that quoting process from weeks to days to hours to minutes.

ID: I'd like to hear a little bit more about why you chose to pursue an AI-based solution. I know that this problem has existed for a very long time. In your opinion, why was AI the best way — maybe even the only way — to really solve this in a comprehensive way?

PN: We looked at a lot of things, like, “Why does this problem exist?” And the thesis is, you have this widget. It starts its life, and you know everything about that part. But when it gets sold through the channel and hits 10 distributors and a thousand end users, there's 1,101 different representations of that part, typically. So, we said, “What if we could just go into these systems?” I saw it when I was in the channel. Why AI? Because we could actually go in and read these things in natural language.

So, the timing of launching this product with where the technology was really made a lot of sense to be able to train a model regardless of naming convention, regardless of how dirty or incomplete the data was. Because that's probably not going to change, right? Trying to find perfect data is like trying to achieve world peace; everyone would like it, but it’s probably not going to happen anytime soon. And it inhibits so many outcomes. Users spend too much on inventory. There's a lot of tail spend and uncertainty, [and with] distributors, it limits what they can sell. It limits the scale in which they can sell it. So we wanted to build an agnostic tool that could overcome that data problem and get to the outcomes that people cared about.

ID: I think a tool like this that can enable real-time collaboration is going be of interest to distributors of every size. Without getting into any kind of hard cost, what is the entry point for, say, a smaller distributor? Is this something that's an accessible solution to them or is this something where you're targeting larger accounts?

PN: As we build out this solution, there are going to be entry points and levels where we can overcome and remove a lot of the manual challenges and give some really cutting-edge technology to companies that wouldn't be in a position to either build it themselves, hire to build it, or buy your traditional big ERP system solution. And we can be kind of plug-and-play with where they're at today, but prepare them to solve the problems and integrate with the technologies that they'll have years to come. So yes, we're building this where, for a small investment, there is a very trackable ROI. Because the value proposition to distribution is to know more of what your customers and prospects are buying. So, you can sell more, you can service better and really be who you are.

Trusted SupplyVerusen

Trusted SupplyVerusen

PN: Yeah, I think so. I think it still lingers depending on who you talk to. But I think with a lot of implementations and use cases and purpose-built applications [with] AI and machine learning — whatever flavor of that you're implementing into your supply chain and those technologies that you use — you're seeing how it augments people. And it can give you more efficiencies and remove a lot of the manual processes that challenge these organizations from doing a lot of things that they know they want to do.

And I think the big thing for this industry, knowing that we're going through a big generational shift, is that there's a lot of knowledge that lives in the heads of every one of your experts across your sales team and your customer team and your product experts. This is an opportunity to transfer that knowledge and prepare yourself, or future-proof the business. This is a great way to start small and then look at ways that you can drive big outcomes.

For more information, visit www.verusen.com.