At last week’s 2014 NAW Executive Summit, Guy Blissett – wholesale distribution lead for IBM and author of NAW’s Facing the Forces of Change – warned an audience of wholesale distribution company executives to be on the lookout for a very disruptive technology: 3D printing. Recently 3D printing took another leap forward when Michigan Technological University scientists invented a 3D metal printer available at a relatively affordable price — around $1,500. So what do businesses need to know about 3D printing?

In October of 1913, Henry Ford's entire automobile factory began building its vehicles using a continuously moving assembly line. This revolutionary step changed the manufacturing game at the time, cutting the production time for the Model T down from over 12 hours to fewer than 6 from start to finish.

Could 3-D printing, also called additive manufacturing, revolutionize the production industry to the same extent as Ford's assembly line? When Michelangelo was asked how he sculpted the famous David statue, he's reported to have simply replied, "I just chipped away everything that didn't look like David."

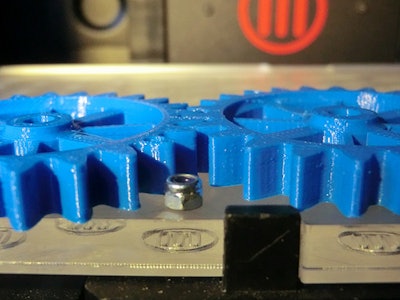

Three-dimensional printing takes the opposite approach Michelangelo used to sculpt David and the opposite approach traditional reductive manufacturing uses to create products. Instead of starting with a single block of material and reducing the material layer by layer until the final project is complete, 3-D printing starts from scratch and adds layers of materials using a computer generated design. It's an additive process that prints only the necessary layers using only the necessary materials until the final product is complete, with no excess of wasted time, materials, money or effort.

This backwards approach could be just the game-changing wake-up call manufacturing and logistics industries need. Here are five reasons why 3-D printing has the potential to revolutionize industries and change the production game for years to come.

1. Three-dimensional printing increases production speed while reducing costs. Consumer goods like clothing, shoes, household items and mechanical parts can all be printed using 3-D technology and submitted to engineers for review. With 3-D printing, revisions are simple to make and mass production of identical goods is affordable and quick. If 3-D printing could be reproduced for large-scale manufacturing, assembly lines wouldn't be as central to the production process, saving the manufacturer time, labor and distribution and handling costs.

2. Consumer demand will have more influence over production. Increased efficiency in the manufacturing stage along with the possibilities of customization offered by 3-D printing could re-establish how manufacturers respond to customer demand. Manufacturing could become more consumer-based and responsive to the current market and its needs. Consumers could have greater input in the final product and could request to have it produced to fit their particular specifications.

3. Instead of outsourcing, we could return to "near-souring" and U.S. production. If production costs with 3-D printing influence an overhaul of global supply chain costs, the lower cost could make outsourcing labor to the West unnecessary. Remote production in a lower cost market could be replaced by manufacturing facilities located on domestic soil, or even in Europe. These facilities would be located closer to the consumer, allowing for a more flexible and responsive manufacturing process, as well as greater quality control.

4. The need for global transportation is significantly decreased. With manufacturing sites located closer to the end destination, all distribution could be done with fleet tracking technology that saves time and energy costs. Truckers currently pull long hours to distribute mass quantities of goods across the nation. But, with smaller batches created to respond to a current demand — and products manufactured closer to the final destination — long trucking hours could be significantly reduced. This would aid EOBRs in keeping our truckers awake on the road and lower distribution's environmental impact.

5. Logistics companies could offer more comprehensive, start-to-finish services. With 3-D printing technology in-house, logistics companies could take on more of a fourth-party logistics (4PL) approach instead of a third-party logistics (3PL) approach. With 3PL strategy, a logistics company only serves one specific function in the entire supply chain process. With a 4PL strategy, logistics companies can manage the entire process — that means managing production, truckers, design and more. This opportunity provides room for growth, expansion and transformation.

Before 3-D printing can truly change the manufacturing game, it has to be scaled up for mass, mainstream manufacturing. It's already happening at Align Technology in San Jose, California. The company uses 3-D printing to create custom plastic molds to help straighten teeth in place of using traditional metal braces. There's even a home market for 3-D printers, with machines like the Cube 3D allowing tech lovers to dabble in manufacturing from home. Though 3-D printing still has advances to make before completely replacing traditional reductive production, the benefits and added manufacturing efficiency are too great to overlook for much longer.

Danielle M. writes on behalf of OmniTracs, Inc. She is a part time student at The Kelley School of Business studying supply chain management and marketing. She has a special interest in how small changes to either manufacturing or trucking, like adding EOBRs to fleets or 3D printers to manufacturing, can have huge effects on the supply chain. She also enjoys studying lean manufacturing techniques, and hopes to put her knowledge to use when she graduates.